Advanced Compaction Simulator

STYL’One Evo - The Most Versatile Compaction Simulator

The STYL’One Evo is the most advanced compaction simulator with integrated analytical software and multi-layer capability, allowing R&D at production speed. The machine is equipped with a unique drive technology in a compact footprint which is ideal for the laboratory environment. The simulator can operate in a displacement mode to replicate any rotary press, or in a compression force mode where the system will produce tablets at preset force targets. Tableting has never been so easy to investigate, from pure API characterization and formulation development to scale-up at production speeds.

Single-Punch

Multi-Layer

tablet press

SINGLE-PUNCH

MULTI-LAYER CAPABILITY

MAX. 120 KN

FULL INSTRUMENTATION AND DATA ANALYSIS

eChalk Talks Webinar

Watch our webinar, which is part of a series of eChalk Talks hosted by the American Association of Pharmaceutical Scientist. The webinar took place on November 3, 2021.

Frederick J. Murray, Director, Global Sales KORSCH AG, focuses on the fundamentals of compaction simulator design, and presents several case studies in which tablet properties produced on a compaction simulator are correlated with tablets manufactured on a high-speed production press.

You need to register to watch this recording.

Designed for Pharma & Nutraceuticals

The STYL’One Evo is an easy to use, easy to clean R&D press. Due to the streamlined design of the compression zone only a limited number of components need to be removed ensuring a higher level of serviceability. The working area permits a fast and easy cleaning. All optional accessories are just as easy to install. The STYL’One Evo is a flexible research tool that can easily be adapted to the amount and type of product to be processed.

Advanced Instrumentation

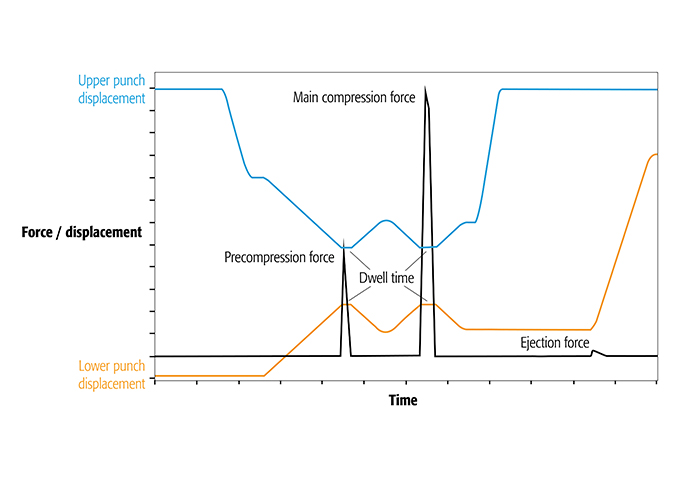

The STYL'One Evo is designed with the most advanced instrumentation to measure the upper and lower compression force and punch position. Mechanical deformation is measured and compensated by the software.

- Precompression force

- Main compression force

- Ejection force

- Upper punch displacement

- Lower punch displacement

- Radial die wall pressure (option)

- Take-off force (option)

Powerful Software Platform

Analis software controls the STYL’One Evo, collects, computes and analyzes the generated data by plotting a wide range of parameters including manufacturability, tabletability, compressibility and compactibility. Customized plots for any data parameters are easily developed to explore porosity, ejection stress, elastic recovery. The HMI simplifies the design and execution of experiments. Tablet tester data can be uploaded automatically to support subsequent reports and graphs.

- Understand and formulate your product

- Develop any type of tablet

- Scale-up to production

- Study dry granulation

Filling Solutions

With a wide range of filling options, the STYL’One Evo is a flexible research tool that can easily be adapted to the amount and type of product to be processed.

- Manual filling: only a few grams of material

- Gravity feeder: low amount of material

- Tapping gravity feeder: low amount of material and/or poor flow properties

- Paddle forced feeder: challenging formulation and/or mini-tablets

Flexible Configuration

The STYL’One Evo permits the production of tablets up to five layers with three different products. A core feeding system permits automated positioning of cores onto the powder bed for core placement applications.

- Quick conversion between the different tablet formats

- Retrofittable at any time

- Multi-layer and Tab-in-Tab software module

Lubrication Pack

This optional module communicates with the STYL'One, is synchronized with the position of the punches and controls the spray duration. This system allows the lubrication of the die and punches to avoid die sticking / tightening without blending lubricant in the granulation. Equipped with 4 wheels, it can easily be positioned near the STYL'One.

Simulation of any Roller Compactor

Lab-size roller compactors have identical roller diameters of those installed on production-scale machines, requiring a large amount of powder, whereas this unique tool can simulate roller compactors with a very limited amount of product.

- Roller compaction software module

- Specific roller compactor profiles

- Quickly target a specific solid fraction

- Dry granulation feasibility assessment

Containment Solutions

KORSCH offers a wide range of containment solutions on most machine models, including DryCon® and WipCon® executions. With proven solutions across the full containment range (OEB 3, OEB 4, OEB 5), KORSCH provides a fully turnkey system which is engineered to meet the specific requirements of the project. In partnership with the customer, KORSCH specialists define critical process parameters, including containment requirements, peripheral integration, and automation design. KORSCH engineers are expert in developing the concept, execution, integration, and final SMEPAC testing to fully validate the containment capability.

STYL’One Evo DryCon®

The STYL’One Evo DryCon® is an advanced compaction simulator with the flexibility to produce single and multi-layer tablets. The DryCon® execution permits contained access to the compression zone and eliminates the requirement for personal protection equipment (PPE) during operation.

STYL’One Evo WipCon®

The STYL’One Evo WipCon® is an advanced compaction simulator with the flexibility to produce single and multi-layer tablets in an isolator. The negative pressure control and monitoring combined with air filtration and safe cleaning drastically reduces the operator exposure. The tablet press can safely run while the operator performs other tasks inside the contained chamber like weighing, hardness measurements or cleaning.

STYL' One Evo Downloads

Download our brochure or have a look at the technical data: