XL 4004 SFP

SINGLE-FUNCTION PLATFORM

XL 4004 SFP - Single-Sided High-Speed Rotary Tablet press

The XL 4004 SFP is a single-sided high-speed rotary tablet press dedicated to single-layer tablet production. The XL 4004 SFP offers streamlined product changeover, unique accessibility to the compression zone and extremely quiet operation. Offering a 100 kN pre and main compression capability, a maximum press speed of 120 RPM, and an extended feeder length, the SFP is geared for high-speed production, with a maximum output of 338,400 single-layer tablets per hour. An ergonomic and accessible design permits the fastest changeover of any machine in its class.

MAXIMUM EFFICIENCY IN SINGLE-LAYER

338,400 Single-Layer Tablets/h

Integrated Electrical Cabinet

Extended Filling Length

Compression Dwell Bar

Food & Confectionary Applications

The machine complies with the highest standard in GMP- and all valid FDA-regulations. Each machine can be configured to meet specific customer needs like:

- Special shape tablets

- Ring Formats tablets(center pin)

- Chewing Gum Tablets

The 4th Generation

The XL 4004 offers a new level of innovation and advancement, while maintaining the flexibility that is the hallmark of the XL 400 design. Smarter and featuring a complete new control system interface, the machine offers an intuitive operating experience. The integration of the electrical cabinet, a sealed machine design without cooling fans or vents, and the use of an advanced torque drive enhance the proven design of the XL 4004 platform.

One Common XL 4004 Platform, Two Machine Models

The XL 4004 design offers a single-layer only (SFP), and a flexible single and multi-layer (MFP) capability in two machine models that share a common platform, and fully interchangeable components. Further advantages are the identical control systems and HMI environment, process equivalent design for direct product transfer or the common procedures for setup, changeover, and turret exchange between both machines.

Superior Accessibility

The innovative carrier plate design of the XL 4004 eliminates the traditional corner columns and offers extreme access to the compression zone. The combination of smooth surfaces and quick-disconnects permits fast cleaning and changeover. The routing of the dust extraction hoses through a dedicated chamber contributes to the great serviceability of the XL 4004.

Streamlined Turret exchange and Product Changeover

The turret design permits the removal of the complete turret, cam tracks, and press tools. A lightweight lifting arm is mounted on the internal lift device and the turret is staged for removal. A simple push-button triggers a safe, effortless, and semiautomatic turret removal sequence to place the turret on the transport cart.

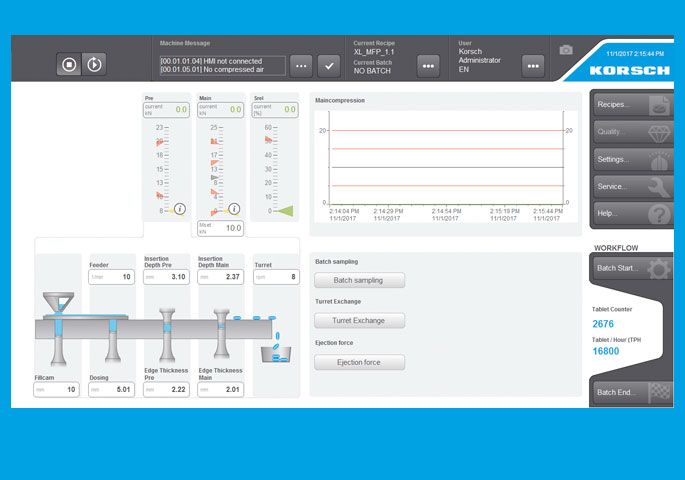

Smart HMI

The control system interface provides an intuitive operating environment and Smart-Touch HMI, which permits move, zoom, and scroll gestures.The HMI environment offers a comprehensive on-board help capability, which includes a vast array of multi-media help files to present procedures and to support operation and maintenance.

Minimal Noise and Vibration

The unique and patented design of the carrier plate, with dampers, fully isolates vibration from the head piece and machine base. The result is:

- Very low noise emission < 80 dB(A)

- No vibration transmission to the floor of the compression room

- No segregation of powder in the feeding system which can occur with machine vibration

Containment Solutions

KORSCH offers a wide range of containment solutions on most machine models, including DryCon® and WipCon® executions. With proven solutions across the full containment range (OEB 3, OEB 4, OEB 5), KORSCH provides a fully turnkey system which is engineered to meet the specific requirements of the project. In partnership with the customer, KORSCH specialists define critical process parameters, including containment requirements, peripheral integration, and automation design. KORSCH engineers are expert in developing the concept, execution, integration, and final SMEPAC testing to fully validate the containment capability.

XL 4004 SFP DryCon®

The XL 4004 SFP DryCon® is a single-sided single-layer only high-speed rotary tablet press for processing highly active but not highly toxic ingredients. The DryCon® execution permits contained access to the compression zone and eliminates the requirement for personal protection equipment (PPE) during operation.

XL 4004 Downloads

Download our brochure or have a look at the technical data: